Uncover the Durability and Detail of litho printing

Uncover the Durability and Detail of litho printing

Blog Article

A Comprehensive Overview to Comprehending Litho Printing Techniques

The world of litho printing, a technique stemming from the late 18th century, is a remarkable mix of history, science, art and development. Stay with us as we journey into the captivating world of litho printing.

The Historical Advancement of Litho Printing

The historic trajectory of litho printing, a critical development in the realm of communication, is a fascinating story of human ingenuity. The procedure developed with the advent of the rotary press, which greatly increased productivity. Each stage of litho printing's development showcases mankind's unrelenting quest of effectiveness and quality in visual interaction.

Decoding the Science Behind Litho Printing Inks

Relocating forward in the expedition of litho printing methods, the focus currently shifts to the science behind litho printing inks. The structure of these inks, their drying out procedure, and color mixing strategies form the backbone of this complex art type. Recognizing these components is critical to grasping the craft and accomplishing the desired print results.

Structure of Litho Inks

In lithographic printing, the essential role of litho inks can not be overstated. Pigments, the color-providing elements, are finely ground bits put on hold in the car, a liquid that brings the pigment onto the printing surface. Each element plays an important component in the final print's top quality, making the accurate formulation of litho inks a complex scientific research.

Ink Drying Process

From the composition of litho inks, focus transforms to the interesting process of ink drying out. The drying procedure is important, as it influences the final print's top quality and longevity. Two primary methods are utilized in litho printing: oxidative drying and absorption. Oxidative drying out entails the ink reacting with oxygen airborne to form a difficult, dry film. This approach offers a durable finish, however can be slower compared to absorption. Absorption, on the various other hand, includes the ink leaking right into the paper fibers, which is a quicker procedure however can lead to much less lively colors. The option between these methods is reliant upon aspects such as print speed demands, the paper type used, and the preferred surface.

Color Mixing Methods

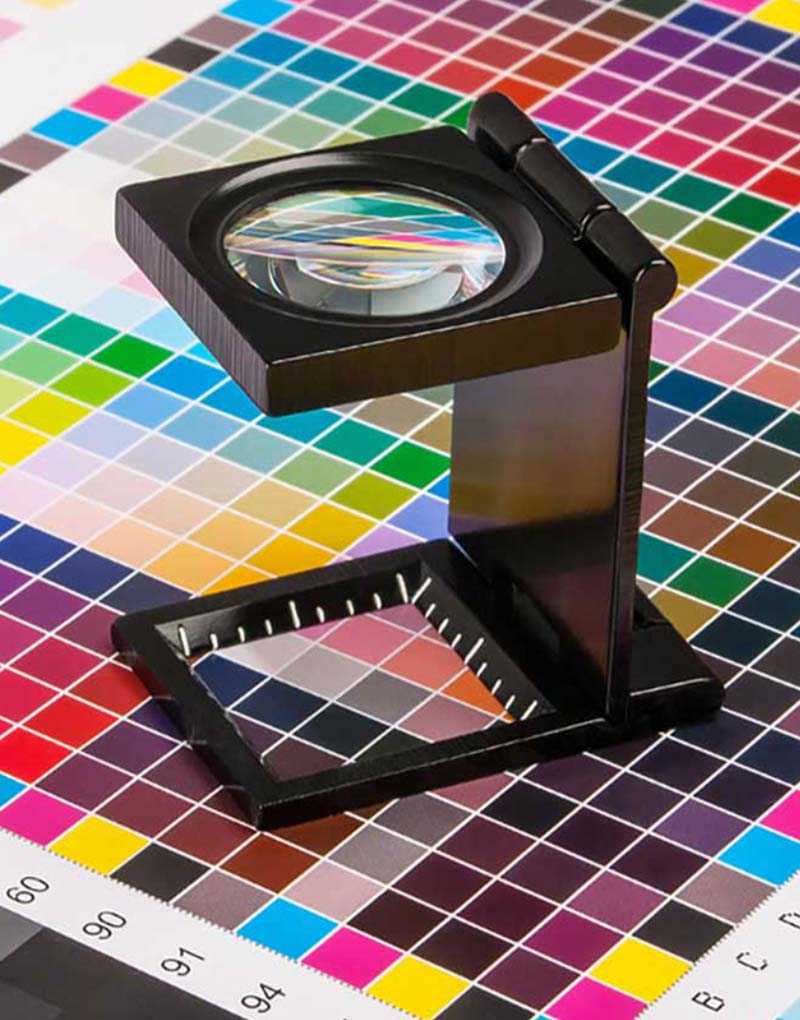

While the drying process plays an essential role in litho printing, the science of shade mixing methods holds equivalent significance. This is a complex process that includes the careful blending of primary colors: cyan, magenta, and yellow, in differing proportions to accomplish a wide variety of tones. The addition of black ink, understood as 'vital', helps in regulating the intensity and deepness of the shades. The science behind litho printing inks likewise considers the openness of the ink, which affects how shades overlay and mix. To accomplish an effective color mix, print professionals should also understand the complexities of ink actions, color concept, and the physical properties of the substratum on which the ink is used.

The Art and Design Aspects in Litho Printing

Litho printing takes a breath life into check it out art and layout via its one-of-a-kind elements. Litho printing fits a selection of colors, enabling artists to develop vibrant and vibrant prints. This combination of precision and convenience makes litho printing a favored selection for many musicians and developers.

Modern Applications of Litho Printing Strategies

Litho printing methods have actually found considerable use in the modern business sector. Its impact and importance continue to grow with the introduction of new innovations and innovations in the area. This section will certainly discover these contemporary applications and the transformative duty they play in the printing sector.

Industrial Litho Printing Utilizes

In today's electronic age, one could wonder concerning the importance of standard printing methods. Litho printing remains a crucial component of the business field. High-volume printing tasks, such as the production of books, newspapers, and product packaging, count on litho printing for its ability to provide premium photo high quality and price look at this now performance. The process, which involves moving a tattooed picture from a plate onto a rubber covering and then to the printing surface area, supplies unequaled consistency. This makes it suitable for work calling for a big print run. Litho printing also offers a wide shade range, remarkable to that of electronic printing. This makes it the best choice for tasks that require vivid, premium color recreation.

Developments in Litho Printing

Pressing the boundaries of conventional methods, modern-day improvements have sustained a host of advancements in litho printing. One popular advancement is electronic litho printing, which incorporates the virtues of digital technology with litho's premium output. These developments underscore the long-lasting relevance of litho printing in the modern globe.

Exploring the Process of Litho Printing: Step by Step

Challenges and Solutions in Contemporary Litho Printing

Despite the precision and custom that litho printing happily upholds, it is not without its collection of modern challenges. One of the most widespread concerns include the high first arrangement price, difficulty in printing variable information, and environmental problems because of chemical usage. Services are emerging as innovation evolves. Digital litho printing permits economical brief runs and very easy personalization, addressing the issue of variable information. Environmentally-friendly inks and much safer plate-making processes mitigate environmental worries. Additionally, advancements in automation have lowered labor costs, additionally democratizing the lithography process. Hence, while there are difficulties, the litho printing market is proactively adapting to satisfy them head-on, ensuring its importance in the future.

Verdict

Finally, litho printing, with its rich background and clinical intricacies, holds a considerable place in the print market. As the guide discloses, it's discover this info here a synthesis of art and modern technology, with modern advancements ensuring its relevance. The sector encounters challenges that need cutting-edge solutions, with an emphasis on automation and sustainability. The future of litho printing pivots on its capability to adapt to these transforming demands, attesting its long-lasting value in an evolving market.

Report this page